About us

Production:

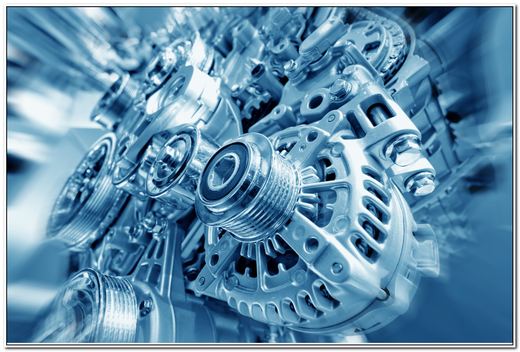

Welcome to our Production Department, the beating heart of our metal processing company. Our state-of-the-art facility boasts a range of modern machining centers, including Mitsubishi, Okuma, and Mazak, enabling us to tackle even the most demanding projects with ease. In our Production Department, we specialize in a variety of services tailored to meet your needs:

- Serial and small-scale production of critical parts: We excel in delivering consistent quality and precision, whether it’s a single piece or a large batch production run.

- Prototyping: Leveraging cutting-edge 3D printing technology, we bring your designs to life quickly and accurately, allowing for rapid iteration and refinement.

- Electrochemical coating: Our electroplating services ensure durable and corrosion-resistant finishes for your components, enhancing their longevity and performance.

- Test bench manufacturing: We design and fabricate custom test benches to meet your specific testing requirements, ensuring the reliability and functionality of your products.

- Assembly: From individual components to complete products, our skilled team meticulously assembles each piece with precision and care, ensuring the highest quality standards are met.

Engineering

Our engineering division serves as the backbone of our operations, driving innovation and excellence in metal processing. Our dedicated team of highly skilled engineers and technologists possesses extensive expertise in the field, ensuring that we deliver superior solutions tailored to meet the unique needs of our clients.

- Our engineering department is committed to pushing the boundaries of what’s possible in metal processing. We leverage cutting-edge technologies and advanced methodologies to develop parts, components, and mechanisms that exceed industry standards.

- One of our primary objectives is to help our clients achieve their goals while maximizing efficiency and minimizing costs. Our engineers work closely with clients to understand their requirements and objectives, offering innovative solutions that streamline production processes and reduce overall expenses.

- At Synergy, we understand that every project is unique. That’s why we offer personalized engineering services tailored to meet the specific needs of each client. Whether it’s developing custom parts, optimizing existing designs, or providing technical support, our engineering team is dedicated to delivering solutions that exceed expectations.

- With practical experience spanning various sectors, including robotics, mechanical engineering, and the food industry, our engineering division has established a reputation for excellence in both Ukrainian and foreign markets.

Quality assurance:

Quality assurance in a metal processing company ensures that all products meet the required standards of quality, reliability, and performance. It involves implementing processes and procedures to monitor and control every stage of production, from raw material sourcing to final product delivery.

- We conduct regular inspections at various stages of production to check for defects, dimensional accuracy, and adherence to specifications.

- We utilize advanced testing equipment and techniques to analyze the physical and mechanical properties of our products. This includes material composition analysis, hardness testing, and performance testing under various conditions.

- We continuously review and optimize our manufacturing processes to improve efficiency, reduce waste, and enhance product quality. This includes implementing lean manufacturing principles and utilizing advanced technologies.

- Our team undergoes extensive training and certification programs to ensure they have the necessary skills and knowledge to maintain high quality standards. This includes training in quality control techniques, equipment operation, and safety protocols.

- We value feedback from our customers and use it to continuously improve our products and services. Customer satisfaction is a key metric in our quality assurance efforts, and we strive to exceed customer expectations in every aspect of our business.

What form of cooperation do we offer?

Prepare the necessary information.

We prepare commercial proposal.

Manufacture the product.

Quality control and delivery.

We hope for a long-term partnership.