Services

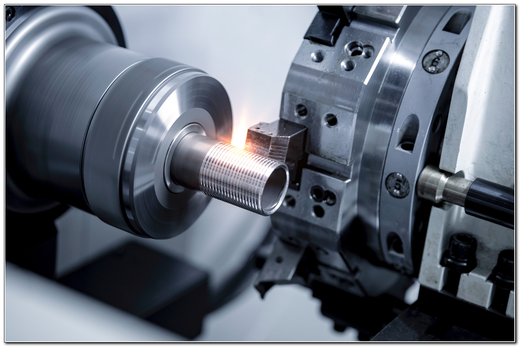

Turning operations:

- Capability to manufacture parts with high requirements for parallelism, coaxiality, and ovality, adhering to the strictest quality standards in the shortest possible time.

- We optimize technological processes, allowing us to reduce costs and increase production efficiency.

- We shorten production times without sacrificing quality, thanks to advanced technologies and meticulous planning.

- Our qualified staff has over 5 years of production experience and continuously improves their skills.

- We guarantee processing precision to micron-level accuracy to achieve the highest product quality.

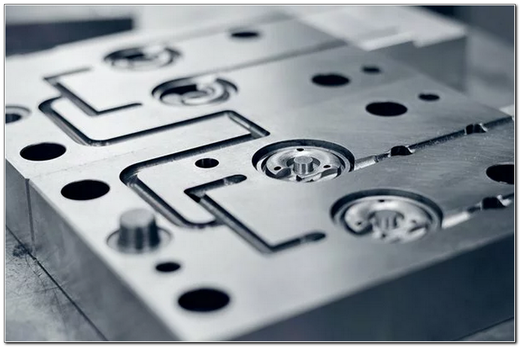

Milling services:

- We use a modern fleet of Okuma, Mazak, and Mitsubishi equipment for precise and complex operations.

- A precise marking system for blanks and further setup in the processing zone to achieve the necessary baselines.

- Production of parts with 7th-grade tolerances with minimal deviations, meeting the highest standards in various industries.

- Ability to manufacture parts from various materials, including stainless steel, aluminum, titanium, alloys, and other specialty metals, taking into account specific customer requirements.

- Ensuring reliable quality control at every stage of processing, including the measurement of geometric parameters to ensure compliance with technical specifications.

Design and manufacture of tooling:

- We have broad experience in optimizing production processes, which in most cases is achieved by developing and manufacturing specialized tools.

- Precise, in some cases precision, fixturing helps to significantly reduce the cost of equipment changeovers, reduce the human factor, and improve the quality of manufactured products.

- Our own production facility, equipped with modern equipment, allows us to manufacture tooling of any complexity within the dimensions of our equipment. A highly skilled team of specialists will help develop and implement your projects.

Manufacturing of highly loaded shafts:

- Dimensional Inspection - Ensures that all components adhere strictly to engineering specifications before the manufacturing process commences. By utilizing advanced measuring instruments, we guarantee precise dimensions and geometry for shafts, which is fundamental to their subsequent operation.

- Non-Destructive Testing and Failure Analysis - Encompasses visual inspections, ultrasonic, and magnetic testing, enabling the detection of internal defects without compromising the material. Additionally, we conduct failure analysis based on statistical data, allowing us to refine manufacturing processes and prevent potential future issues.

- Shaft Design with Strength Calculations, Bending, and Torsional Stress Analysis - Employing modern mechanical modeling software, we can predict shaft behavior under various conditions and minimize the risk of failure.

- Hydrostatic Testing and Spark Testing - This process verifies the leak tightness and durability of shafts under high pressures. If necessary, we also perform spark testing, an additional quality assurance step, especially for components used in critical systems.

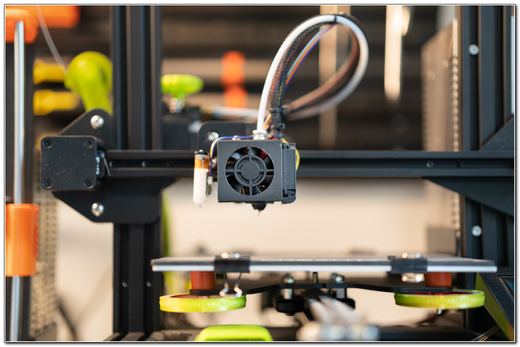

3D printing:

- Prototyping parts, assemblies, and products using 3D printing technology.

- The ability to integrate multiple parts into a single component.

- Technology for producing custom tooling equipment.

- Rapid prototyping reduces time to market, providing companies with a competitive advantage.

- Reduction of material waste, as 3D printing uses only the necessary amount of material to produce parts.

- Flexibility in design allows for easy modifications to models without significant costs.

- Lower overall production costs due to reduced expenses on tooling and materials.

- The ability to quickly test and verify concepts before mass production.

Welding services of any complexity:

- We perform welding of any complexity for various objects and materials.

- TIG welding for stainless steel and non-ferrous metals.

- Semi-automatic welding for precise and fast component joining.

- Electrode welding of metal structures with high strength.

- Repair and modification of existing metal structures on-site.

- Precision welding of small parts and assemblies with high-quality seams.

- Design and fabrication of complex structures on request.

- Reliable solutions for durable metal structures of various purposes.