3d printing services

3D Printers in Mechanical Engineering

3D printing allows engineers to solve a wide range of tasks incredibly quickly, efficiently, and accurately:

development of new parts and mechanisms (creating concept models, test samples);

modernization of existing systems and individual components;

repair and replacement of failed parts.

Using 3D printing during development or in the technological process allows for the creation of higher-quality products at lower cost and faster.

Advantages of Using 3D Printing in the Manufacturing Industry

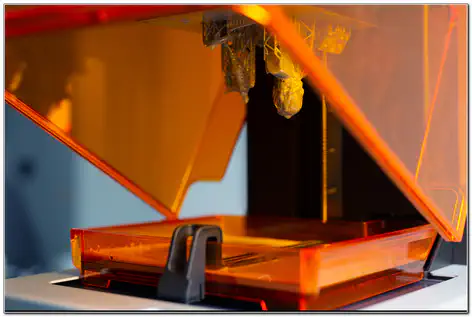

The ability to produce geometrically unique parts that cannot be created by traditional methods. What seemed like science fiction yesterday, today you can manufacture in just a few hours on a 3D printer.

Reduction in production time. A 3D printer can produce a finished product in a few hours, while traditional technologies require weeks, and sometimes months.

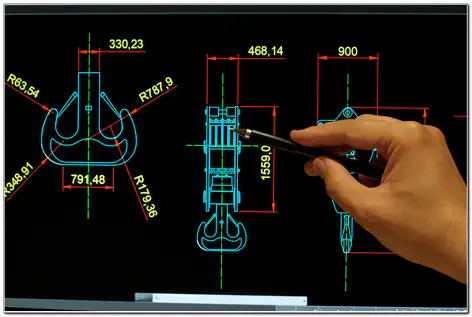

Elimination of the ‘human factor’ reduces risks and errors. A product created using a 3D printer replicates the CAD model with 99% accuracy.

Improvement in the parameters of finished products: reduced weight, increased precision, and durability. 3D-printed products offer several advantages in their properties.

The ability to control the physical and mechanical properties of parts by mixing different materials (e.g., alloys of different metals).

Tasks in Mechanical Engineering Effectively Solved by 3D Printers

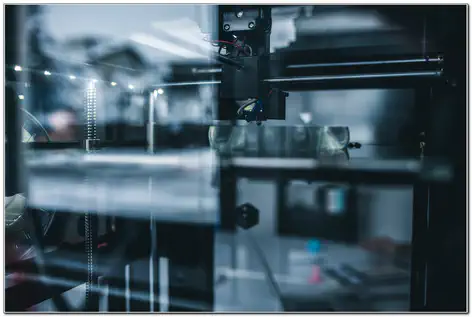

Modern 3D printing systems allow engineers and designers in the mechanical engineering industry to quickly and efficiently solve a wide range of tasks. 3D printers are indispensable both at the stage of creating conceptual prototypes and for the production of finished products.

Prototypes for Testing: Produce prototypes of future products before launching mass production, test them, check their properties, strength, functionality, and fix any deficiencies.

Cases for Devices and Components: Unique cases, walls, mounts, and other accessories for electronic devices and mechanisms that ensure the reliable operation of your developments.

Tooling Production: 3D printing provides the opportunity to quickly produce convenient and effective tooling to accelerate production.

Casting Models: With a 3D printer, you can create high-precision wax models, burnout models, and prototypes for silicone casting.

Ready-to-Use Products: Print parts that can be immediately used in production: mechanical parts, repair components, engine parts, structural elements, and tools.

How to Order Parts?

Get a free quote, start production, and receive your parts with our streamlined process.

Get A Quote Immediately

Email your design to our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed.

Receive Your Part

After all parts pass QC inspection, they will be delivered straight to your doorstep.

Reliable and High-Quality 3D Printing Services

Our 3D printing services provide precision, efficiency, and customization to meet the unique needs of various industries. Using advanced technology and high-quality materials, we ensure the production of durable and detailed prototypes, functional parts, and complex designs.

Whether you need rapid prototyping, small-batch manufacturing, or custom designs, our team is ready to deliver high-precision results with a fast turnaround. Contact us today to discuss your project and bring your ideas to life with cutting-edge 3D printing solutions.