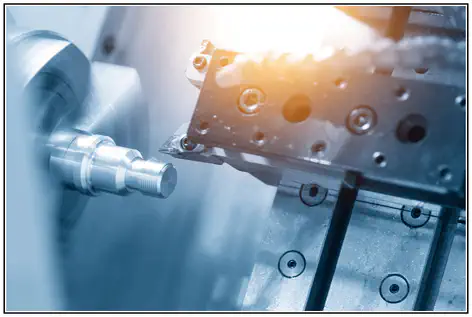

Cnc turning services

Timeframe: from 1 day

The cost depends on:

- volume of work;

- complexity of work;

- availability of material;

- uniqueness of the tool;

- presence of non-standard requests.

Lathe Machining Services

The company «Synergy K» provides metal turning services. Turning is a necessity in most mechanical engineering industries. Not all engineering companies have a full set of machining equipment — and that’s perfectly normal. We offer fast and high-quality metal turning services for those who need finished parts without unnecessary costs.

Our services are ideal for:

- Design bureaus — for creating prototypes and experimental models.

- Small enterprises — for small-batch production.

- Companies focused on assembly — when assembling finished products from pre-made components.

Why Should You Order Turning Works from Us?

Production of small and large batches

Quality control at every stage

Processing blanks from various metals

Manufacturing parts of any configuration and complexity

Our Capabilities

High-precision metal turning on CNC machines in our own metalworking facility. There is an option for processing blanks from various metals:

- steel;

- stainless steel;

- aluminum;

- brass;

- copper;

- bronze;

- titanium.

Metal turning is the most demanded method of mechanical cutting processing and involves manufacturing a rotational figure from a metal blank. The fixed blank rotates around its axis at a specified speed, while a cutting tool made of hard material moves along two coordinates (perpendicular and parallel to the axis of rotation), giving the part the desired shape.

Different cutting tools, rotation speeds, and feed rates are selected for each type of metal and the required surface quality. On a conventional lathe, the setup of the cutting tool, adjustment of the rotation speed, and movement of the cutting tool are done manually by the turner. A CNC lathe in the workshop performs all these operations automatically according to a pre-set program. This ensures high processing accuracy and absolute uniformity of the series of parts.

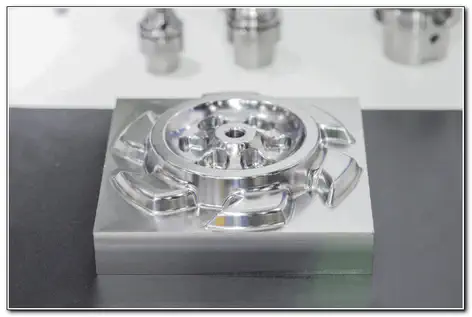

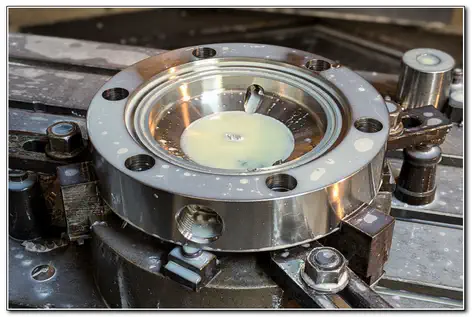

Examples of high-precision turning works:

Advantages of CNC Lathe Metalworking

Our equipment:

Procedure for Ordering and Performing Turning Work

In our company, you can order parts that require the application of other types of metalworking in addition to turning, such as laser cutting, drilling, milling, and bending.

- Our clients can be industrial enterprises, design bureaus, and individuals.

- We perform turning work according to the customer’s drawings.

- The order execution time ranges from 1 day and more.

- Creating a CNC program takes some time and has its own cost. Therefore, the speed of production and the cost per part will be lower when ordering serial production.

- You can order turning work of any complexity from us.

The comprehensive application of metal processing technologies offered by our company allows ordering the manufacture of parts of any configuration and complexity.

What Determines the Prices of Turning Work?

Our pricing for metal turning work is based on an hourly rate, allowing us to optimize costs for both us and our clients. When planning each project, we provide a detailed estimate for future work, which remains unchanged after approval. The cost calculation for metal processing services on a lathe is based on several key parameters:

- The volume of the ordered batch. The larger the order volume, the lower the prices. This allows us to optimize production costs based on the principle of large-scale production and offer more favorable conditions to clients.

- The complexity of the part. The structural features and geometry of the product directly affect the cost, as high-precision turning work on complex shapes requires more processing time. In some cases, multiple methods of working with the blank are applied to achieve the final result.

- Preparatory work. The time spent on programming CNC machines, adapting the project in the software, and setting up production modes is also included in the cost of services.

- Time for turning work. It is determined after analyzing the provided drawing and depends on the technical requirements of the order.

- Material of the blank and additional processing. Materials and the need for additional processing, such as electroplating to improve the operational characteristics of the part, also increase the overall cost of manufacturing.