Design and manufacture of tooling

Tooling in manufacturing: What it is and its types

In the manufacturing industry, tooling is an important process stage for producing high-quality parts that meet specifications.

Transforming raw materials into completed products requires a blend of technology, expertise, and specialized tooling equipment.

But first, you must make the necessary tools. This tool manufacturing procedure has a big impact on efficiency, and precision when producing parts.

What is tooling in manufacturing?

Tooling, commonly referred to as machine tooling, is the process of shaping or forming materials to produce tolerance parts. This involves the use of jigs, molds, patterns, fixtures, and cutting tools to cut, shape, and form the parts. The equipment needed for tooling differs depending on the particular production, the type, and the size of the tooling.

It is important to note that to execute tasks correctly and maintain operations, it’s critical to have the necessary tools. Suppose the manufacturing process is ineffective without the right tools. Moreover, any changes made to the tooling technology directly affect production quantity, quality, and cost.

How to Order Parts?

Get a free quote, start production, and receive your parts with our streamlined process.

Get A Quote Immediately

Email your design to our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed.

Receive Your Part

After all parts pass QC inspection, they will be delivered straight to your doorstep.

Significance of Tooling in Manufacturing

Tooling for manufacturing has a bigger impact on the mass production of goods, as it can speed up production and lower the cost of operation.

Proper tooling is necessary for producing high-quality items quickly.

Manufacturing efficiency and cost-effectiveness

Streamlined manufacturing workflows result from effective tooling procedures. It is possible to produce large numbers of identical parts with little variation thanks to production tooling, particularly in methods like injection molding.

Although the initial investment in production tooling may be high, the long-term cost per unit is frequently much lower than that of other manufacturing processes.

Custom Parts

Tooling makes it possible to create distinctive and customized components, which promotes innovation.

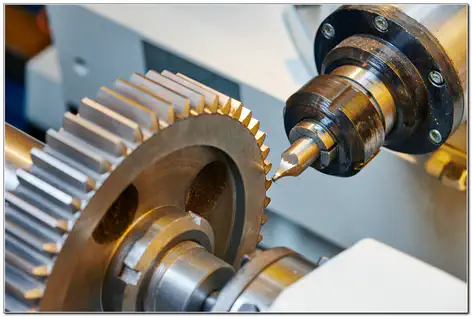

Furthermore, advanced machining techniques like CNC machining, which have revolutionized tooling, now enable sophisticated designs and complex geometries.

Suitable for a Variety of Materials

Tooling is versatile and can be used with a wide range of materials, including various polymers and metals like steel and aluminum.

Therefore, the ability to select appropriate materials for specific applications ensures that the finished product meets the necessary standards for strength, durability, and aesthetics.

What Factors Affect the Cost of Tooling?

Although numerous factors affect tooling prices, they are all connected to the type of material being worked and the tool’s specification.

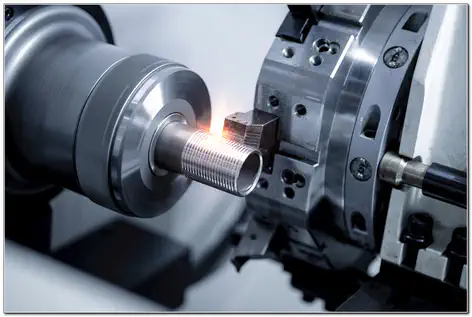

Part Specification

The cost of tooling also depends on the number of operations the CNC machine needs to perform. Simple cuts or bores require fewer tools. Twisting, boring, and intricate cutting will need more tools.

Besides, the parts may need certain surface treatments like polishing or features that other tools can grasp, such as gaskets. Tooling prices will rise with each additional specification step.

Applications

Tools with higher hardness are required to conduct cuts on materials like titanium and hardened steel.

Understandably, these tools cost more than cutting softer materials.

Conclusion

Tooling plays a crucial role in manufacturing, involving the use of specialized tools and equipment to transform raw materials into finished products. The quality of these tools is essential for efficient and timely production.

If you want your tooling service done properly, don’t hesitate to contact us!